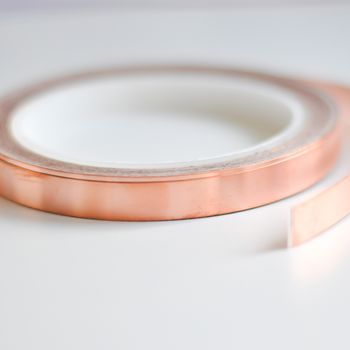

Bronze foils/strips are used for a huge variety of industrial applications, ranging from electrical contacts and membranes to spring elements and switches. The processing industry requires CuSn6 foils with more and more specific characteristics, e.g. significantly higher mechanical load-carrying capacity. To guarantee consistent quality, the mechanical characteristics of the foils must be determined.

The mechanical characteristics of thin metal foils can be determined using the instrumented indentation test (according to DIN ISO 14577). For this purpose the foils are affixed onto a smooth and stable surface. However, if the foil is applied unevenly or if an air bubble is trapped underneath it, the foil will bend while being measured, causing a false measurement of the indentation depth by adding an additional elastic but inconsistent percentage to the measurement result.

With the special foil clamping device from FISCHER, thin metal foils up to 200 µm in thickness can be easily braced over a cylinder, avoiding any critical fixation.

| HM (Martens hardness) N/mm2 | HIT (indentation hardness) N/mm2 | HV (Vickers hardnessderived from HIT) | EIT/(1-vs2) (elastic indentation module) GPa | ηIT (elastic deformation) % | ||

|---|---|---|---|---|---|---|

| strip 1 | X. | 1006 | 1179 | 111 | 97 | 9 |

| s | 19.9 | 27.6 | 2.6 | 10.7 | 1.0 | |

| V% | 1.9 | 2.3 | 2.3 | 11.0 | 11.2 | |

| strip 2 | X. | 1116 | 1311 | 124 | 105 | 9 |

| s | 16.8 | 24.5 | 2.3 | 4.0 | 0.5 | |

| V% | 1.5 | 1.9 | 1.9 | 3.8 | 5.4 | |

| strip 3 | X. | 1573 | 1916 | 181 | 108 | 12 |

| s | 71.8 | 88.5 | 8.4 | 8.0 | 0.8 | |

| V% | 4.6 | 4.6 | 4.6 | 7.4 | 6.6 |

The mechanical properties of thin metal foils can be determined precisely and conclusively with the instrumented indentation test. For this purpose FISCHER provides the measuring system FISCHERSCOPE® HM2000 and a foil clamping device for optimal sample preparation. For further information please contact your local FISCHER representative.